MC-202 Videos

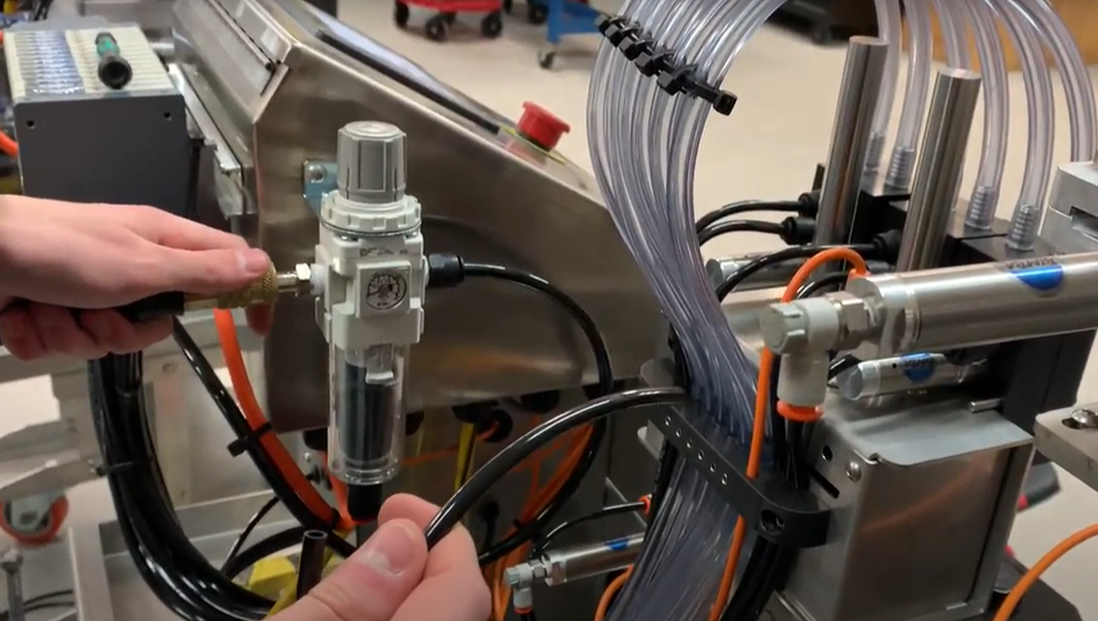

How to Drain your Air Compressor

Prevents air cylinders speed from changing and helps prevent flow controls becoming inoperable

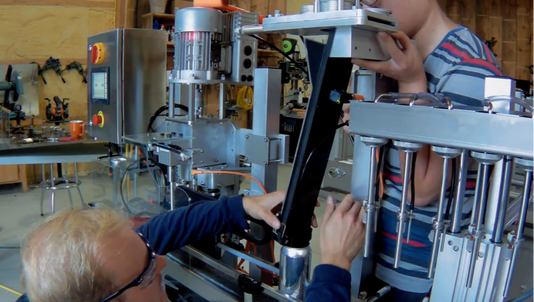

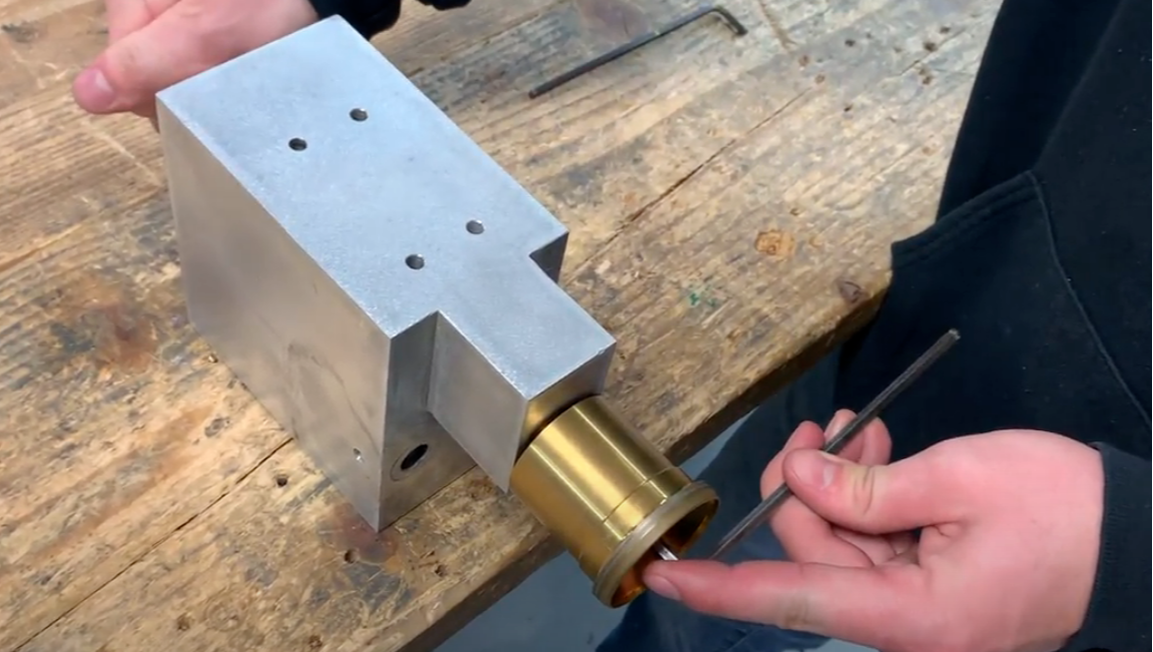

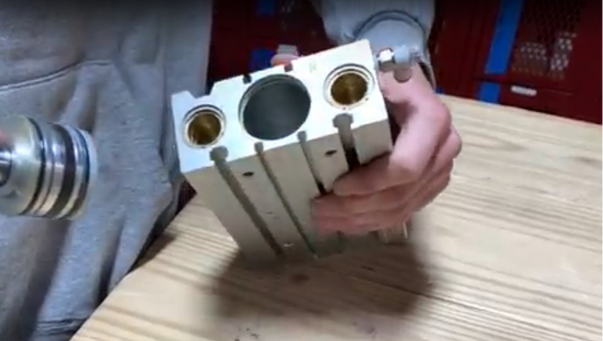

Greasing a MC-202

Prevents air cylinders from leaking prematurely and to keep the seamer running smoothly

Adjusting the Cap Track, Foam Rail and Cap In Place Sensor

Fixes lid application issues and lid shedding issues

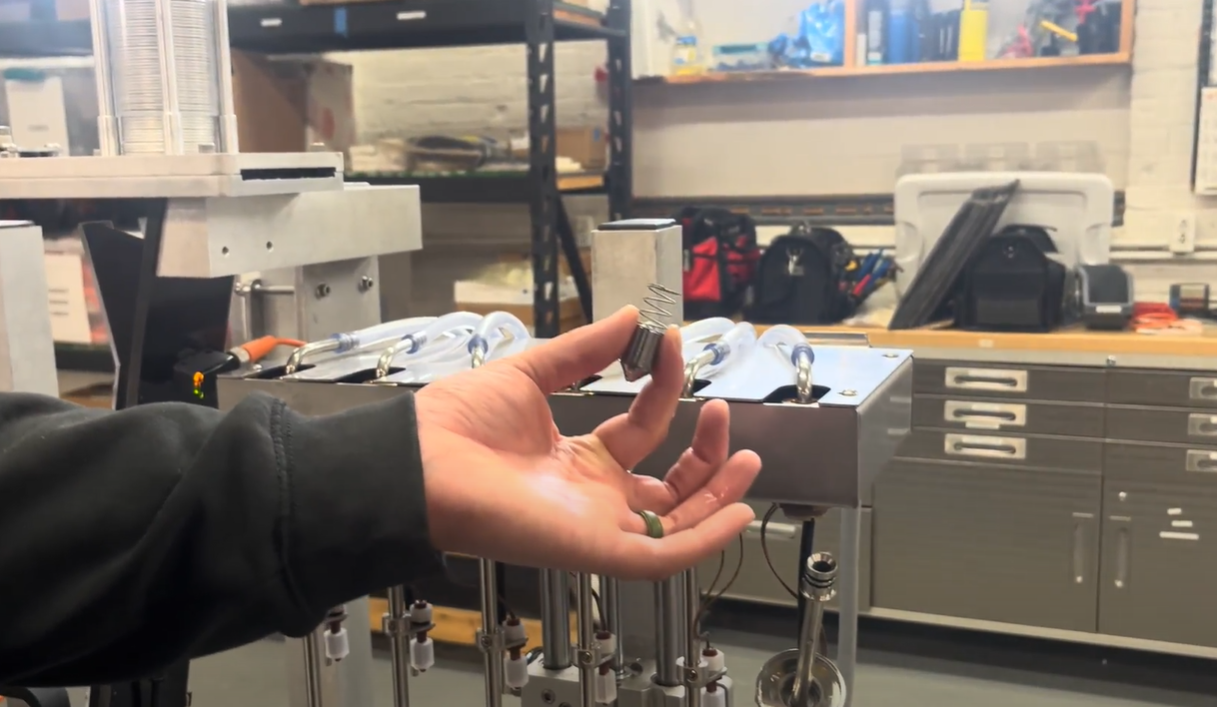

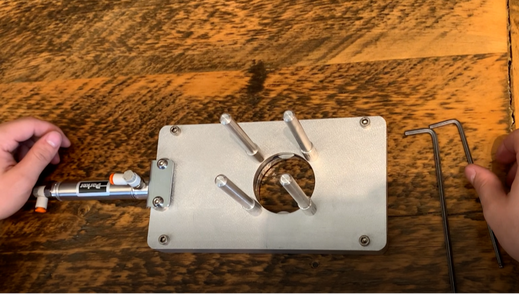

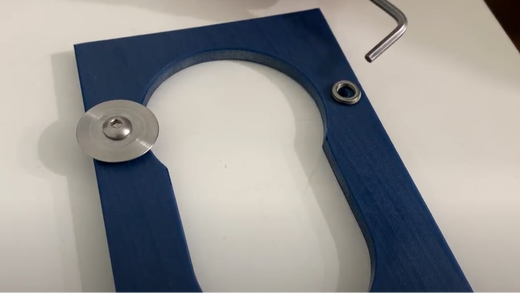

Replacing a Cap Shedder Plate

Fixes a cap shedder that starts slowly not shedding lids correctly and consistently

Setting the Cap Shedder Speed

Fixes a cap shedder that drops two lids when only one should drop, can also fix inconsistent lid shedding

Flipping a Cap Shedder Plate

Will prolong the life of the cap shedder alowing it to drop lids consistently again

Adjusting for 88 Gauge Lids

Confirm you have 88 gauge lids before preforming the actions in this video. If you do have 88 gauge lids this will fix jamming and lids not shedding.

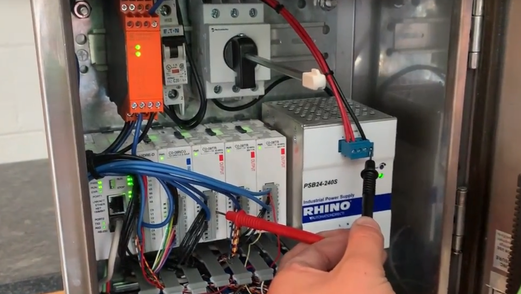

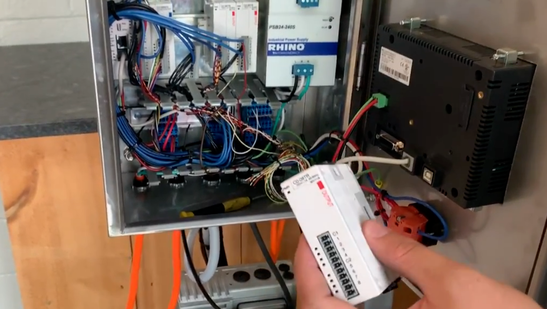

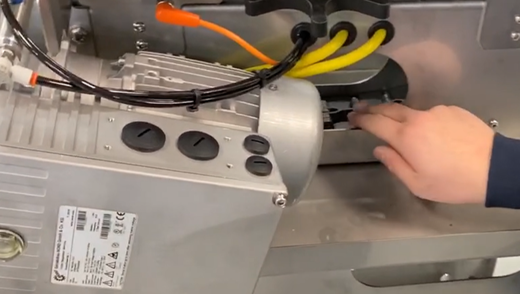

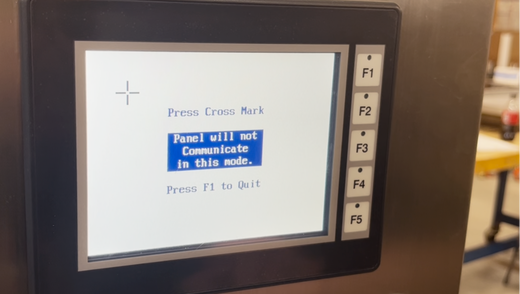

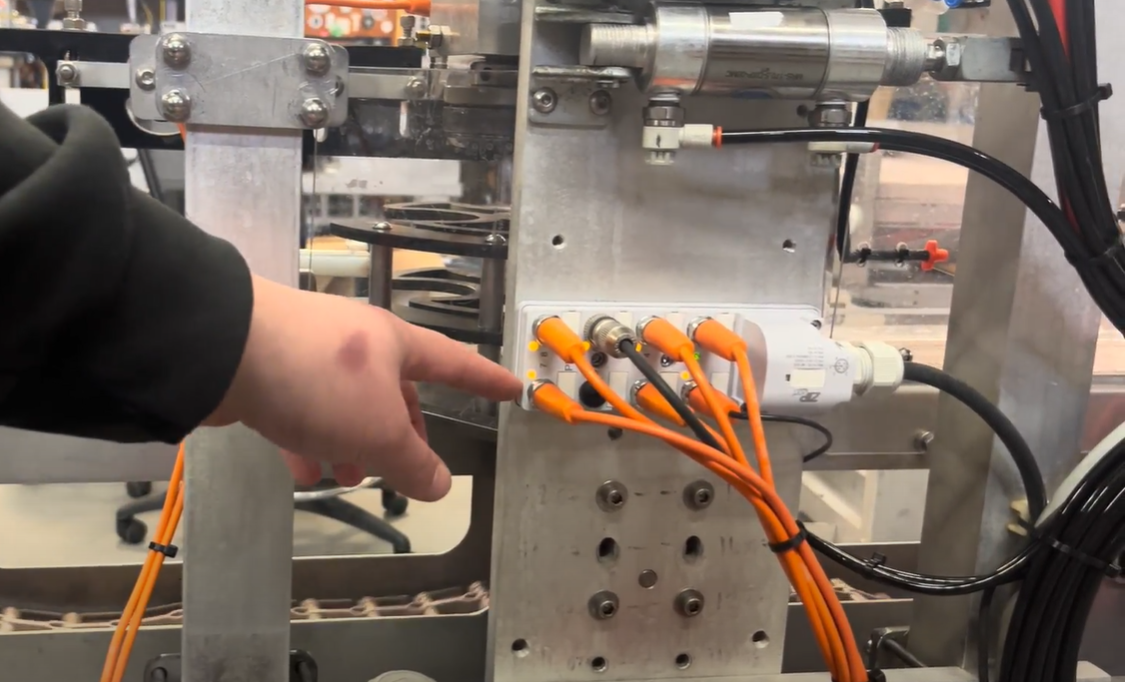

Diagnosing a bad 8 port

Diagnoses why a sensor may be reading but is not causing the machine to react to the input

Cans moving past rinse

Diagnoses a bad rinse valve that can cause cans to move past the rinse station

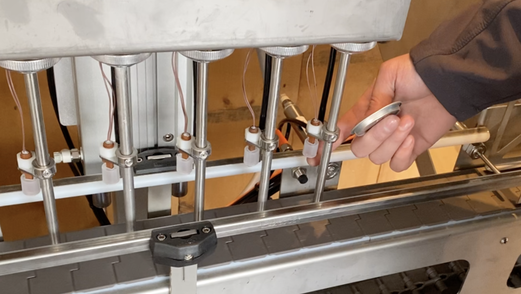

Setting the filler sensor

Fixes CO2 that stays on too long during a fill, also fixes a filler head the rapidly lowers and raises.

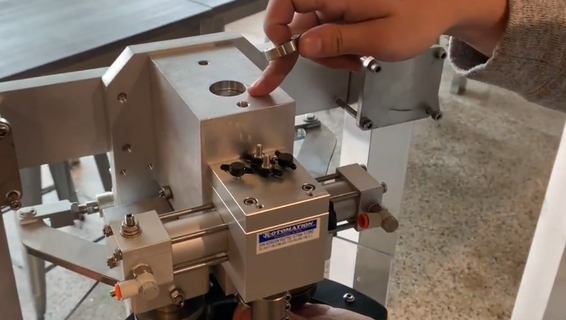

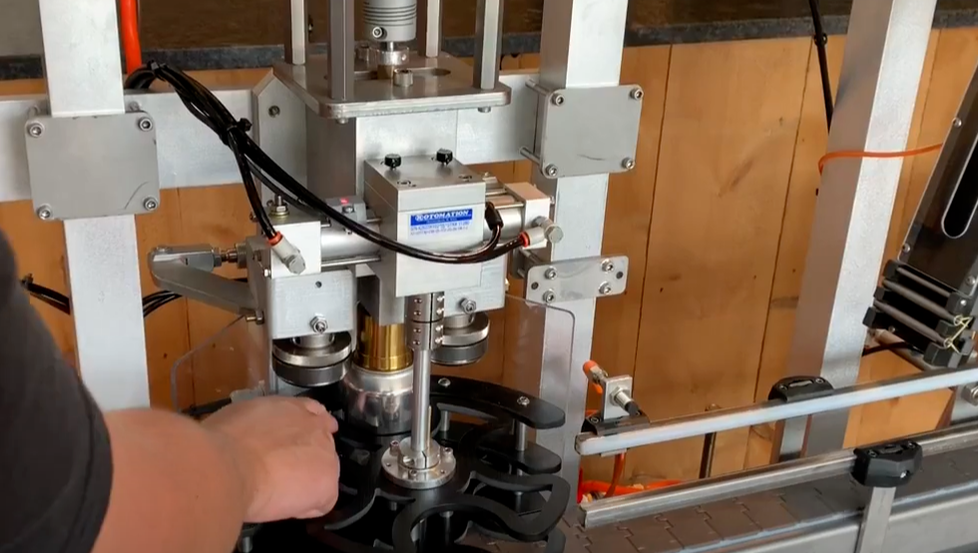

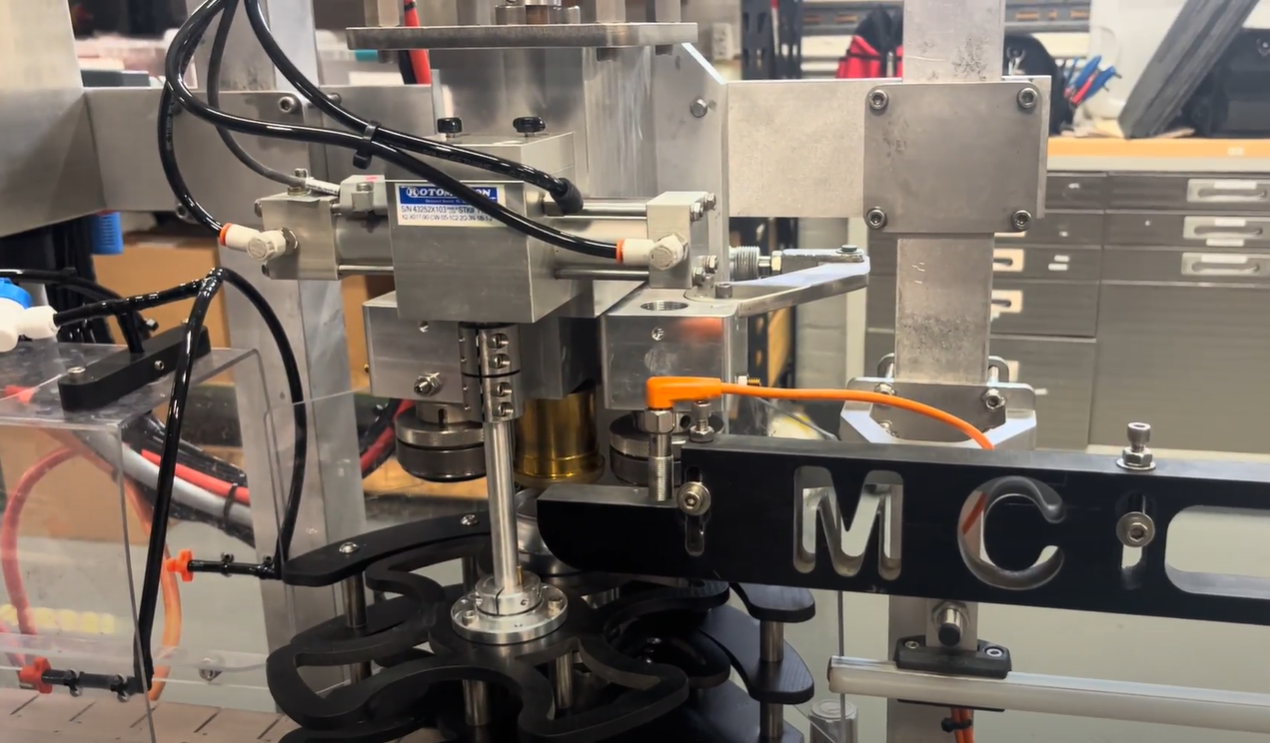

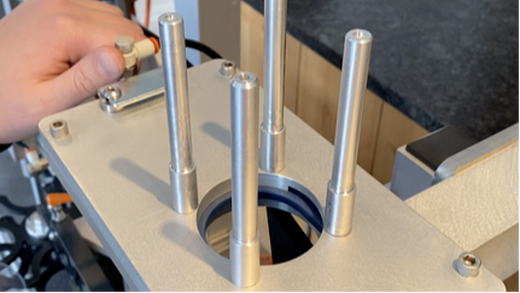

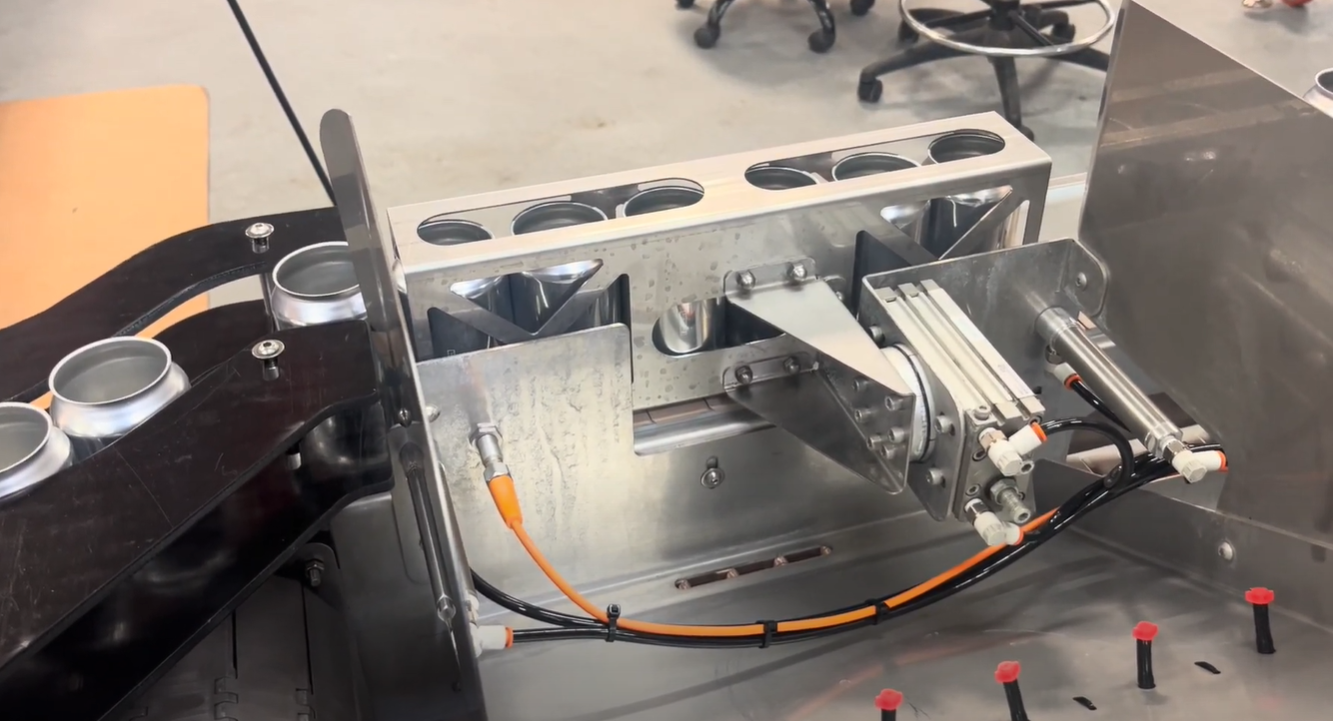

Checking and adjusting shoulder bolts

Can fix inconsistent seams and tooling arms that arent smooth